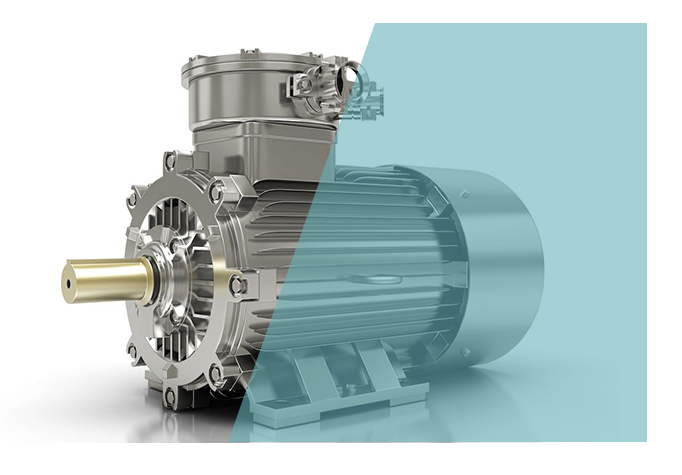

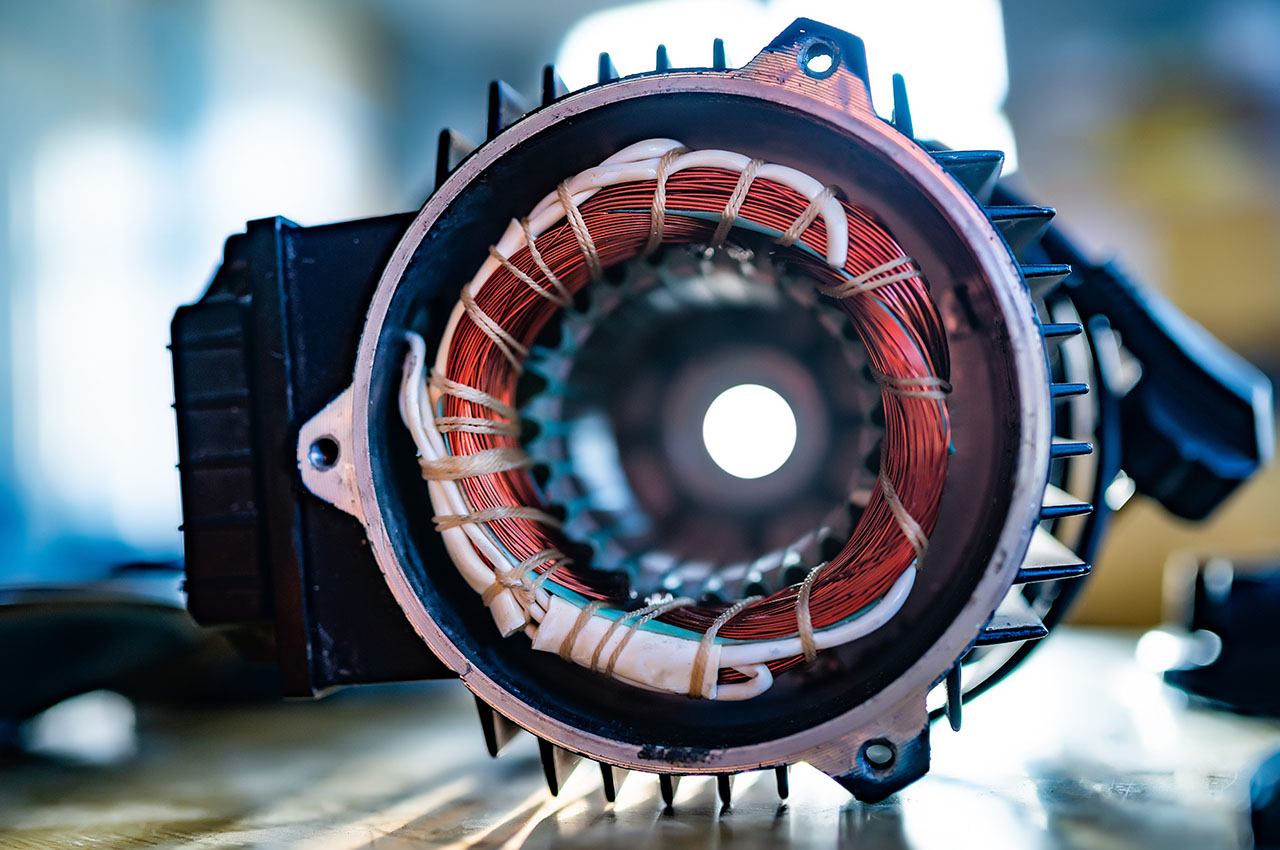

DESIGN AND CONSTRUCTION OF SPECIAL ELECTRIC MOTORS SINCE 1995

SM4E carries out all the activities for the creation of special electric motors: from design to rapid prototyping up to production and integration into market applications such as industry, mobility and energy production. The motors are compatible with a wide range of applications: from electric Power-trains to machine tools, from electric traction to micro-wind power.

DESIGN

– Study of special motors

– Reverse-Engineering

– Thermal optimization

MANUFACTURING

– Pre-series production

– Supporting for motor industrialization and production ramp-up

PROTOTYPING AND TESTING

– Fast prototyping

– Test

– Certification and documentation

INTEGRATION

Integration with control electronics and electric Power-trains.

DESIGN

– Study of special engines

– Reverse-Engineering

PRODUCTION

– Pre-series production

– Supporting industrialization

PROTOTYPING

– Rapid prototyping

– Test

– Certification and documentation

INTEGRATION

Integration with control electronics and electric Power-trains.

THE BEST SOLUTIONS

All SM4E processes are constantly improved and updated to achieve the best mechanical, electrical and thermal characteristic of the motors for the required performances. With the acquisition by HB4, both the end-of-line testing system and the automation processes have been integrated and improved.

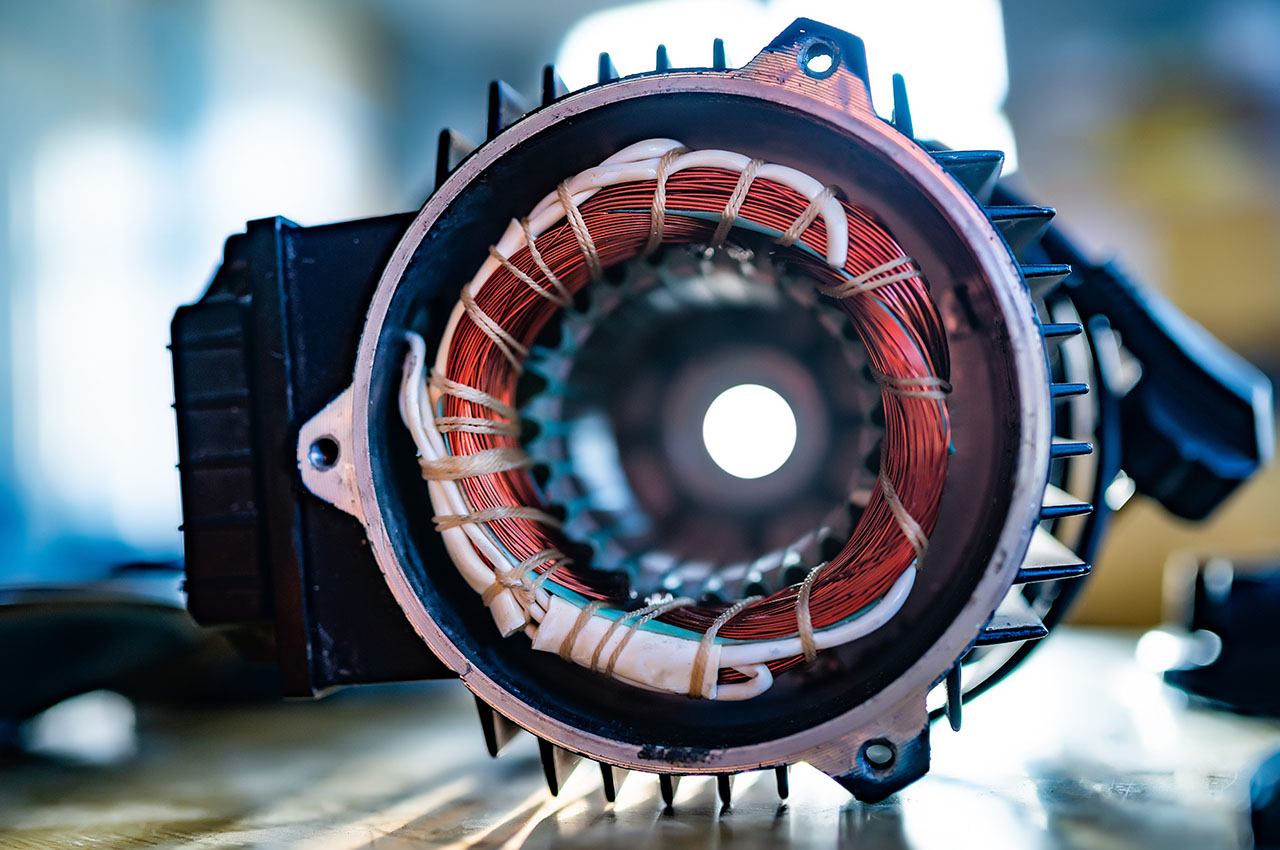

The keystone in the daily development of new motors, aimed at satisfying multiple cases both from a mechanical and electromagnetic point of view, is the synergy between the technical office and the test room; thanks to it, it is possible to carry out a constant R&D program by testing new components, new materials and expanding our range of electric machines.

MOBILITY

2 and 4 wheels vehicles, work vehicles, marine.

INDUSTRY

Printing machines, machine tools, ventilation.

ENERGY

Micro wind power, Micro hydro wind.